Rebuilding the Dream

In the Summer of 1990 everyone I knew was bombing around in Alfasuds, and through them I was introduced to Neville Powell, an accomplished race engineer, fabricator and deep sea diver, who gave me the confidence to have a go at designing my own car. I read all the books I could lay my hands on about chassis engineering and suspension theory, and drew up a list of requirements. One of the biggest problems was how to move the centre of mass forward, closer to the centre of the car. The shape of the Nova almost celebrates the mass of the engine in the tail, leaving few options for mounting the engine within the wheelbase. My thoughts inevitably turned to the Alfasud, with its compact boxer engine mounted longitudinally with the transmission behind it; the low profile of the engine package could be pushed further forward beneath the reclined seatbacks, and the inboard front brakes with integral handbrake would be transferred to the rear. The decision was made – the Alfasud would be the donor car.

I needed an engine and transmission in order to start work on the chassis design, and my friend Smudge came to the rescue. Together with his cousin he went to a car auction and returned with a 1978 Series 2 Alfasud 1.5 Ti. Suffering from terminal rust, the logbook showed the previous keeper was none other than HRH the Duchess of Kent! Smudge dismantled the car for me and I took away a very long list of parts – the engine and transmission of course, front brakes, driveshafts, hub carriers, radiator, header tank, heater box, dashboard, instruments, pedal box, handbrake cable, headlights… even the front grille.

Once the position of the engine and gearbox mountings were established, I needed to design the suspension. This is not an easy task, especially for a novice. Rather than fabricate my own, I started contacting kit car designers who I knew had used Alfa components in their mid-engined cars. First I tried Peter Pellandine, a well-known specialist car designer from the 1950s (he co-founded Ashley Laminates and later the Falcon brand), but his Alfasud powered Pelland coupe project was no more.

Next on the list was Lee Noble, who at the time had had phenomenal success in kit car racing series with both his Ultima and a less well-known Lotus 23 replica. The standard Noble 23, as the Lotus replica was called, used the transaxle, driveshafts, hubs and inboard brakes from an Alfasud. The cast iron bearing carrier and strut suspension was replaced with cast aluminium uprights and tubular wishbones. Although Lee had recently sold the Noble 23 project, he was still able to supply spare parts, so I immediately ordered a full set of front and rear wishbones and a pair of rear uprights. I ordered fully adjustable wishbones instead of the usual rubber bushed items – spherical joints offer near-infinite fine adjustment of camber, caster and toe-in at both ends of the car.

The front suspension required a front steer rack and hub carriers, and here the Alfasud could not help me, so I plumped for Mk3 Cortina front uprights and an Escort steering rack. Together with a set of second-hand SPAX adjustable dampers and £750 worth of spherical joints, my Nova would finally have the handling to match its looks!

Meanwhile, I removed the perimeter bolts holding the Nova body onto the VW floorpan, and with Neville’s help lifted the whole body and canopy onto a wheeled trolley. I then sold the complete rolling floorpan, including the engine and the alloy wheels to a guy named Badger, who put it back under a Beetle, where it should have stayed in the first place.

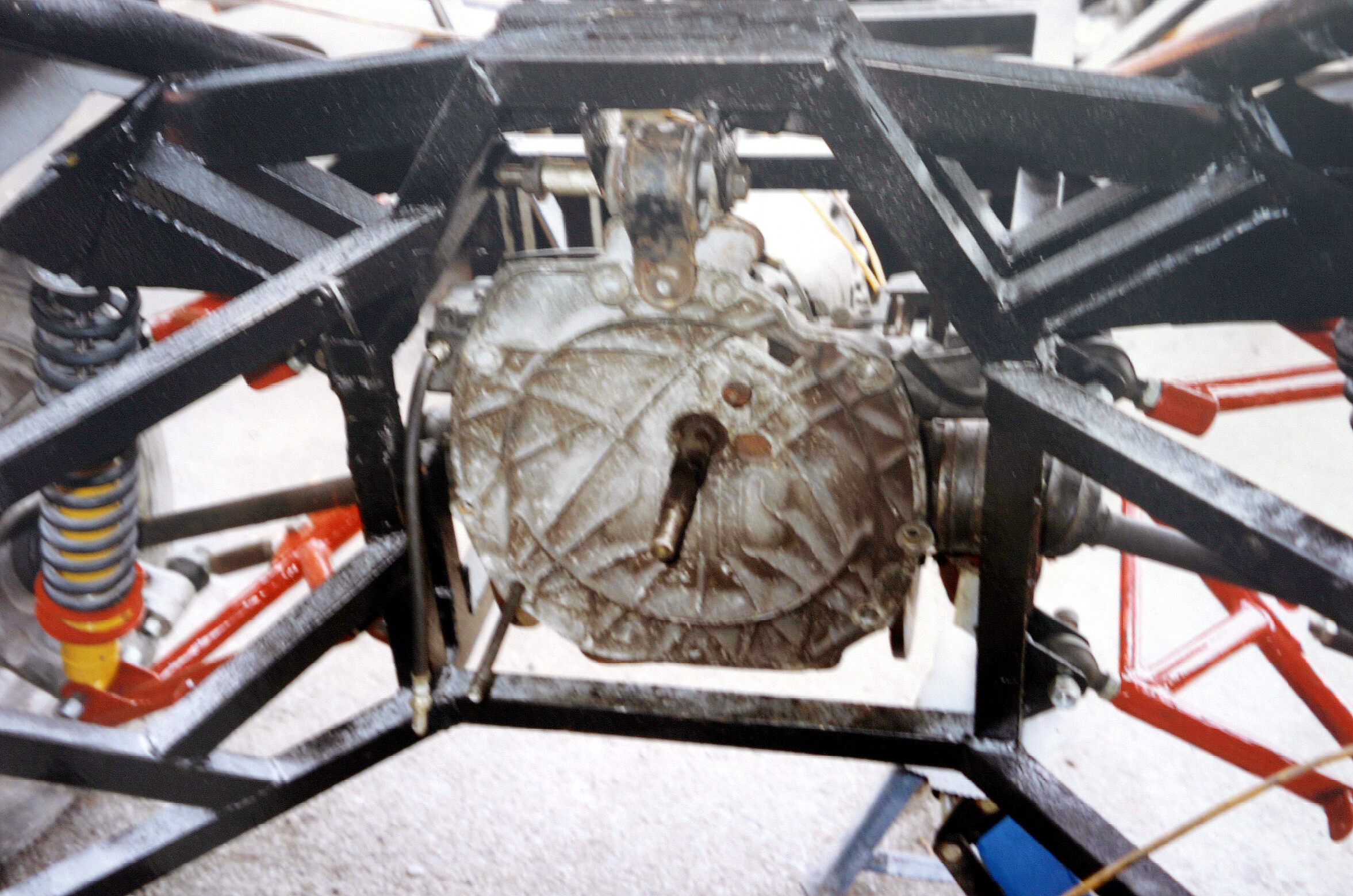

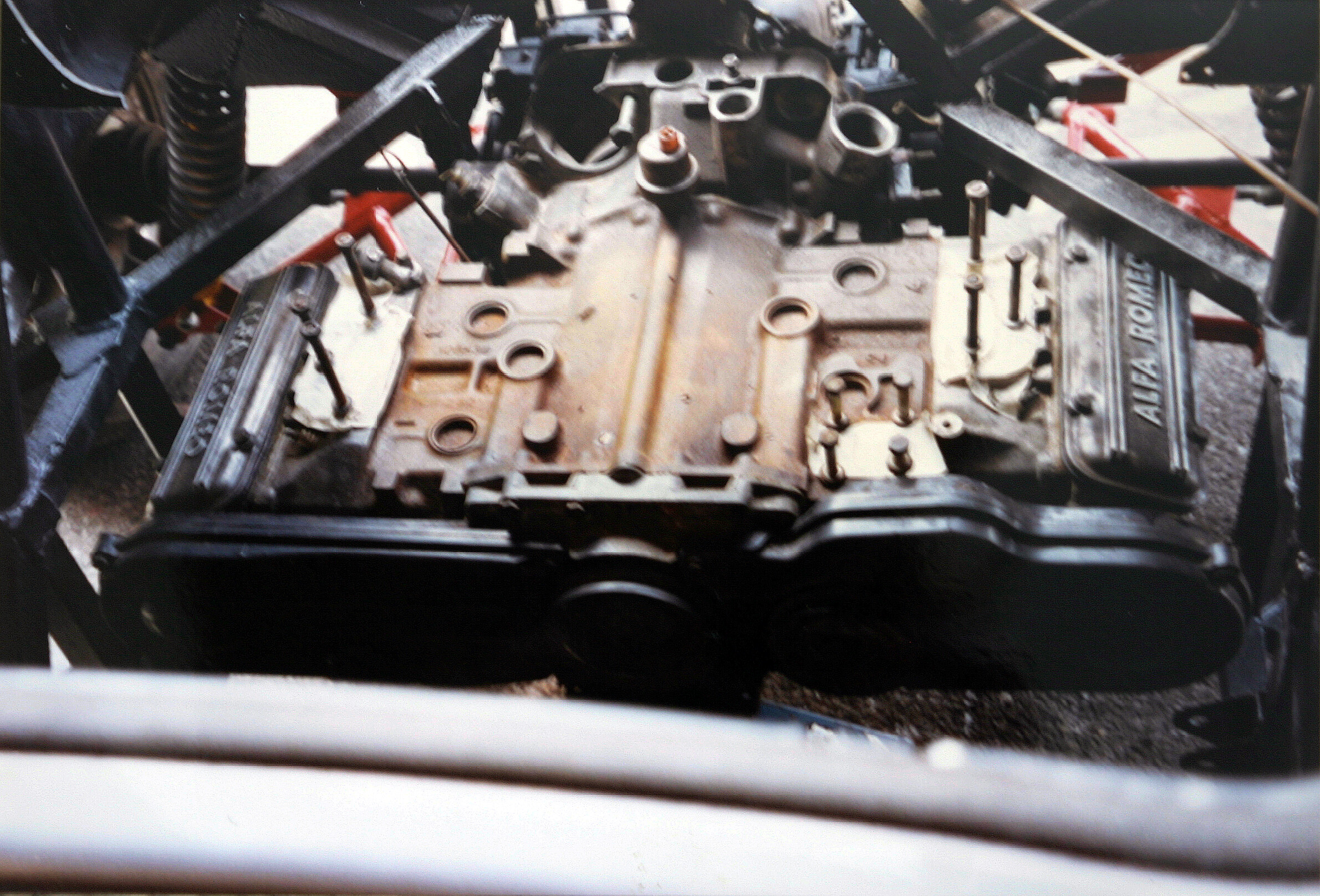

Now I just had the empty Nova shell, sat on a trolley. With the wishbone locations established at both ends, and keeping the original 2.4 metre wheelbase of the Beetle, I began to draw up a tubular steel chassis. A cradle contains the transaxle and rear suspension mounts, with a perimeter frame picking up on the body mounting flange, skinned with an unstressed steel floor. A removable bulkhead separates the engine from the cockpit, and driver and passenger are surrounded by a stout steel framework hidden by the outer sills. Four large diagonal beams, passing above and below the engine cylinder heads attach the engine cradle to the cockpit section. A removable front crossmember carries the Alfasud front engine mount, while a bridge structure over the top of the gearbox bellhousing carries the Alfasud top engine mount and also feeds the rear spring and damper loads into the chassis. Neville also fabricated a substantial rollover hoop, which is welded to the frame and is braced by a pair of diagonal tubes which run back to the gearbox cradle and are welded to the bridge structure for good measure.

Being mid-engined, the gear linkage runs forwards, along the right hand side of the gearbox casing, behind the brake disc and around the engine sump. A pair of aircraft-quality universal joints allow the linkage to attach to a centrally-mounted gear lever, which was topped off with a Fiat X1/9 gearknob rescued from a scrap car. All five gears are in their conventional positions, although a bit more effort is required to change gear due to the short throw of the lever.

Trial fit of 1978 Alfasud Ti gearbox in custom Nova chassis

Early trial fit of 1978 Alfasud Ti 1.5 engine in custom Nova chassis

To be continued...